The new ANTHOGYR Packaging has been thought out for Axiom® and Anthofit® implants, making handling easier and safer than ever. From inventory to patient dispensing, all steps are streamlined.

> Keywords of this new concept (patented system) are SIMPLICITY and EFFICACY

ANTHOGYR has designed a unique implant packaging that features a very simple and yet efficient titanium clamp. It remains in a closed position and positively captures the implant when the cap is on (during transport), and can be released to pick up the implant or if the implant needs to be replaced in its primary packaging intraoperatively. It’s particularly convenient and valuable in post-extraction situations or when drilling adjustments are necessary.

In addition, titanium ensures full preservation of the physicochemical properties of the medical device (i.e. preservation of functional surfaces, no MD contamination). The wide base of the package ensures increased stability on the operative field.

The packaging can be opened with one single hand. The implant is picked up using the contra angle; no need for an implant holder. The closure screw (or cover plug for an Axiom® 2.8 implant) located inside the cap can be easily removed by pulling upward. Six color codes have been assigned to the 6 implant diameters for a quicker identification.

> A clever packaging system

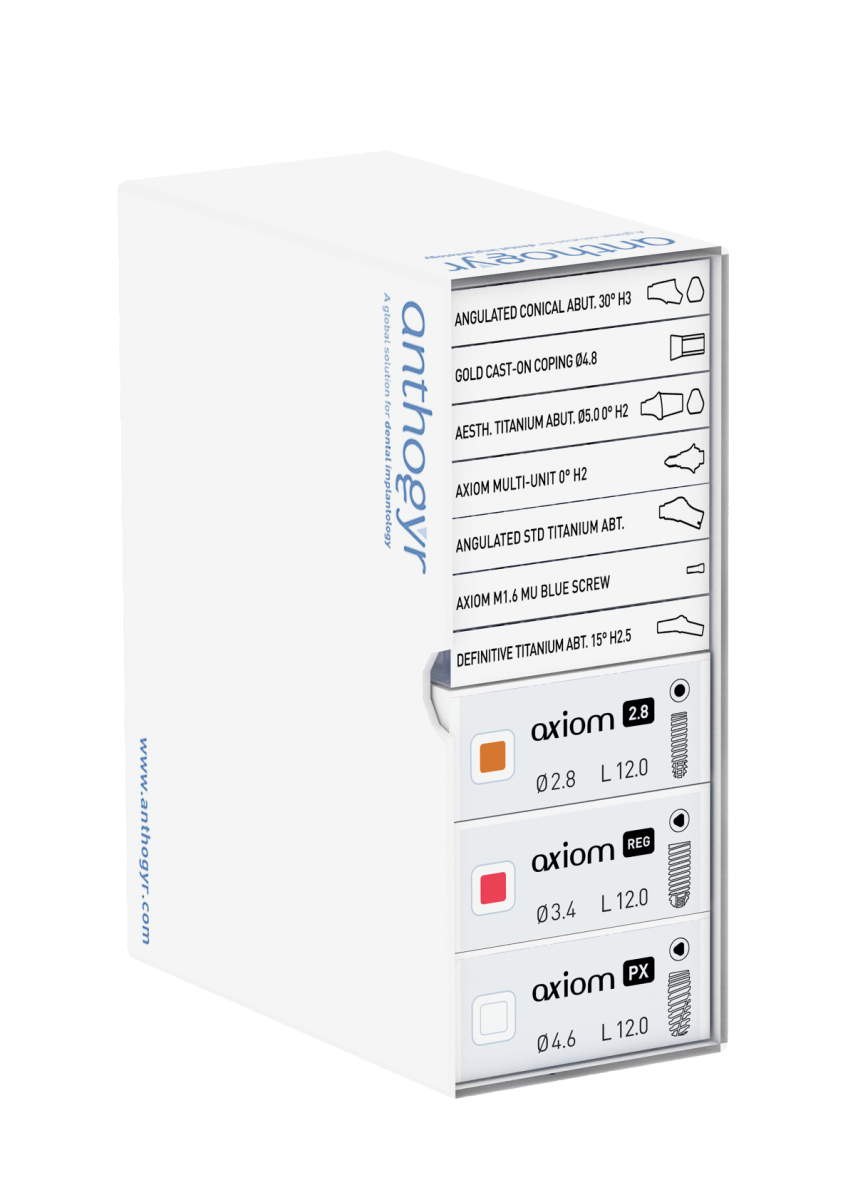

The shipping box also has been redesigned. It is now even more convenient and ergonomic. It can be used both for shipping and office storage of implants and future blisters of prosthetic components.

The primary packaging is contained within a clear blister pack placed in a rectangular cardboard box to facilitate office storage and ranking. The outer box has a safe pre-cut opening in the front, and 4 self-sticking, repositionable traceability labels are provided for the patient's medical record.