The inLab CAD SW 15.0 software has been an indispensable part of the digital workflow in dental labs for over a year now. The extensive update inLab CAD SW 16.0 now offers additional options. The wide range of inLab applications has now been extended even further with new indications, tools and functions as well as the option for additional implant systems and a completely optimized workflow. For the first time, scan data from inEos X5 for suprastructures can also be transmitted to Atlantis®. Dentsply Sirona continues to enable access to individual implant restorations for dental laboratories.

Following the successful market launch of inLab Software 15.0 last year, the first update is now available. The latest inLab CAD SW 16.0 offers new features across all CAD modules. In the Removable dental prosthesis module, dental splints and individual impression trays can be designed for the first time using the new inLab Splint plugin.

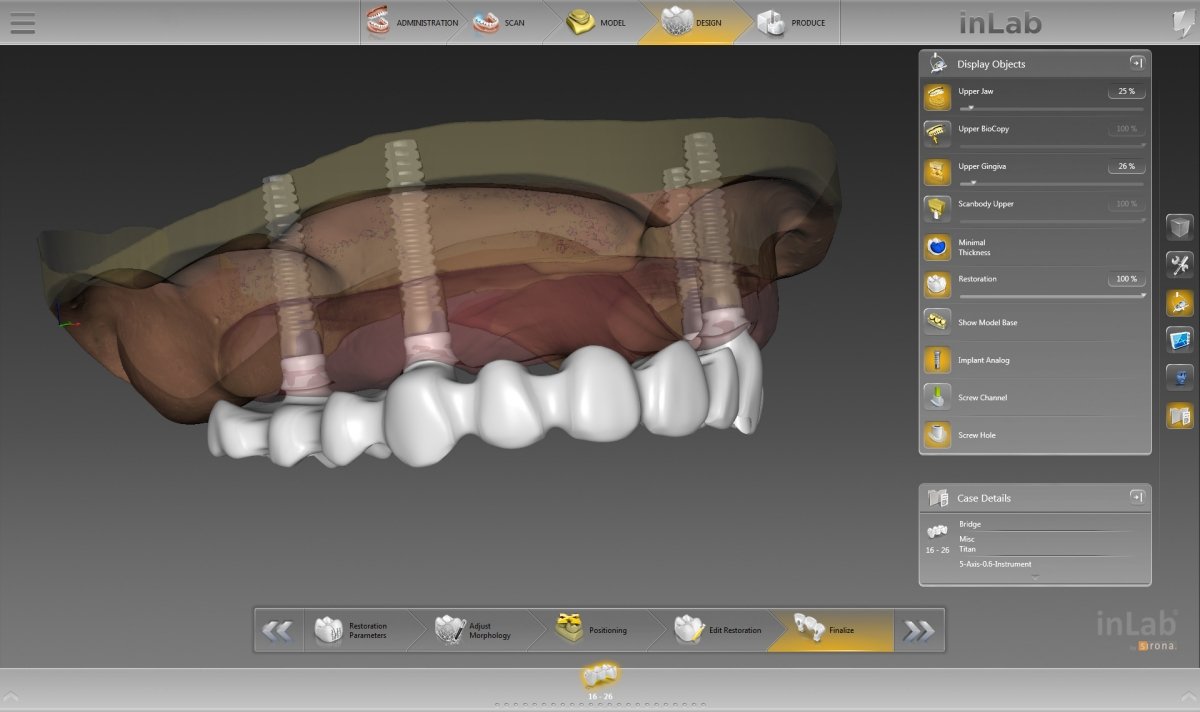

The Implantology module has been extended to include screw-retained bridges and dental bars at implant level, thus allowing the FLO-S Scanbodies from Atlantis® to be scanned and identified with inEos X5 and inLab SW 16.0. Starting next year, the scan data can be transmitted to Atlantis® for the design and production of suprastructures. Coinciding with the introduction of this software, infiniDent, Dentsply Sirona's production center, is launching a new production service for directly screw-retained bridges that have been independently designed by the customer in inLab CAD SW 16.0. The corresponding design dataset can be exported directly from the inLab software to infiniDent for subsequent production. The Atlantis® and infiniDent services will be launched as a beta phase for selected customers in November. After successful completion, it will then be available for all inEos X5 users. For the production of individual adhesive abutments (TiBase), the following implant systems are also supported by inLab SW 16.0: Astra Tech Implant System EV and Ankylos from Dentsply Sirona Implants as well as BioHorizons and Osstem TS.

For the production of restorations on other milling machines, STL data export via the inLab software interface module is required. In addition to the actual STL dataset, the additional *.sci file (Sirona case information) is also created. This supplements the STL data with additional information, such as implant positions, preparation margins, information on materials, etc.

As the only laboratory software on the market with J.O.B.S. (Jaw Orientated Biogeneric Setting), inLab supports rapid patient-specific positioning of teeth with minimal of corrections, even for work over long spans. The inLab CAD SW 16.0 is now extending this convenience with a new function: inLab Check. The new plugin tests the designed restorations with an FEM analysis for critical, strain-sensitive areas and visualizes these areas. The tool offers inLab users practical design support for large, complex cases or where space is constricted.

The inLab CAD SW 16.0 now runs under both the Windows 7 and Windows 10 operating systems. Furthermore, it comes with numerous optimizations in terms of processing power, tools and design options, like screw channel design, additional tooth shapes for the restoration design (for example a third premolar in tight spaces) or the implant-independent tooth position in the design of implant bridges.

In addition, the current inLab CAM Software 16.0 update for the inLab MC X5 and inLab MC XL production units will be available free of charge as an automatic update or internet download in the next few days.

Dentsply Sirona presents inLab CAD Software 16.0

InfoWeb Marketplace