inLab receives added horsepower for production units: inLab CAM SW 16.0 refined and enhanced with more features

Complementing the new inLab CAD software 16.0 from Dentsply Sirona, the latest CAM update inLab CAM SW 16.0 for the inLab MC X5 and inLab MC XL production units is now available. In addition to bolstered indications, expanded material selection and extensive application upgrades, the user-friendly processing of restoration data from other CAD programs has been expanded. These considerable adaptations allow for even more effective use of the 5-axis milling technology of inLab MC X5, offering the end user a quality of restoration never achievable until now.

The CAM update, inLab CAM SW 16.0, designed for inLab MC X5 and inLab MC XL (Dentsply Sirona CAD/CAM) is ready for market on schedule and the release perfectly compliments the launch of the latest inLab CAD SW 16.0 system this November. Drawing on the expansive pool of knowledge derived from highly trained beta testers, experienced users, and many customer and service consultants - wide-ranging advances have been implemented in the inLab CAM software, adding a perceptible boost of stability and user-friendliness for the production machines.

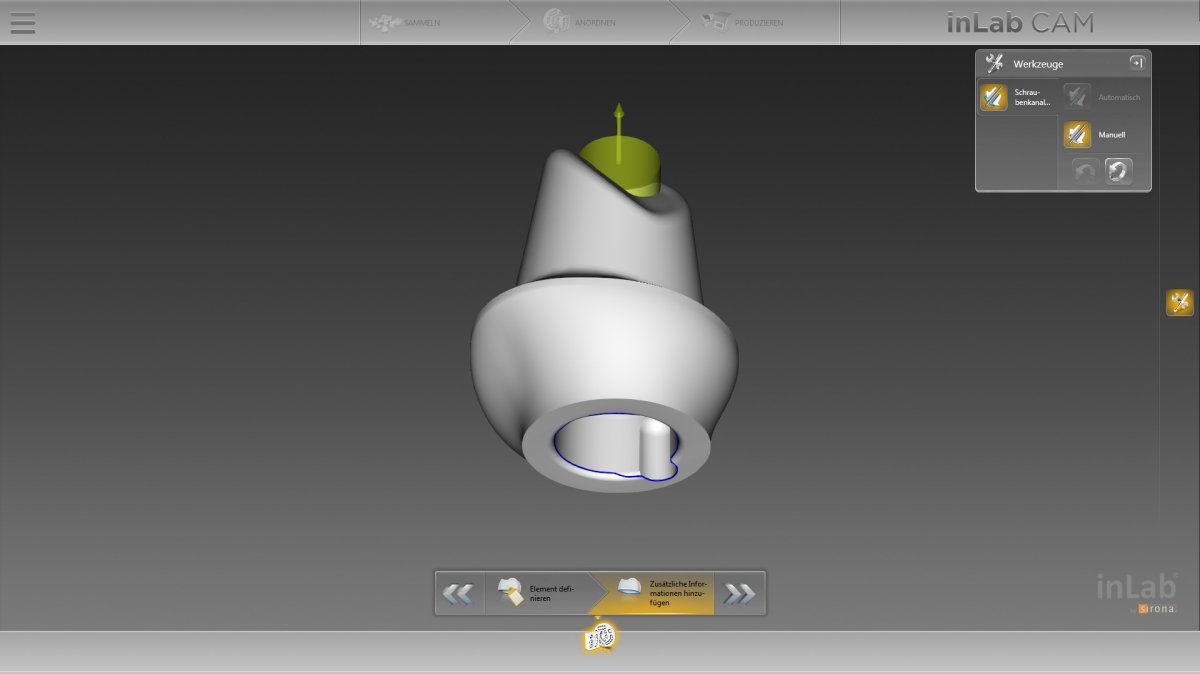

By expanding the STL processing of design data from other CAD software systems, the inLab family increases its range of functionality, making it possible to import implant designs from other systems to be processed in either the inLab MC X5 or the MC XL. By loading XML-based auxiliary files, STL data can now be imported quickly and easily from 3Shape® and Exocad® with no significant additional effort. Essential element information such as restoration type, preparation lines, insertion axes, screw channels, tooth number, and the like, can also be imported if it is present. In addition, several STL restorations can be imported and additional information added to them successively.

For the first time, the inLab CAM SW 16.0 now supports the milling of Medentika PreFace® titanium abutments with the inLab MC X5 production unit in approved countries. The position of the screw channel is determined precisely using the spindle touch scanning process developed specifically for the mill. For milling pre-formed titanium abutment blanks, Dentsply Sirona will soon offer a dedicated inLab MC X5 starter set for Medentika PreFace® abutments with many accessories and specialized tools.

In the latest CAM software, even more individualized placement of restorations in the proposal is now possible, for example, adjusting restorations to best suit color gradients. The software now also includes many tools for handling undercuts, as may be presented. The spindle touch technology of the inLab MC X5 determines the exact block size and position for the material selected. This allows the user to reuse blocks that have residual space for additional restorations. Maximizing the user’s materials allows for greater profitability by using CAM SW 16.0.

The material class coding allows exceptionally simple management of inCoris discs in the CAM software. QR codes are now featured on the blanks and on their packaging. They can be quickly scanned directly into the CAM software of the inLab MC X5 with a webcam. All material information such as blank name, color, height, LOT, sintering shrinkage, and other information is automatically entered into the workpiece overview. Blanks that have been partially machined can be found again later in the software via the QR code. Users save valuable input time, ensure accuracy of critical data and always have an optimal overview of the available blank inventory.

Another new feature of the CAM SW 16.0 is the capability to create a complete history of a workpiece. All essential information on the progress of a job, the elements produced, and all information on materials is now available in the form of a valuable documentation tool for quality management in the dental lab.

The inLab CAM software 16.0 now optimally supports the diamond coated inLab MC X5 zirconium oxide milling burs. These burs prolong their service life as much as five times compared with uncoated milling burs. Further, with new proposal strategies, the user can expect finer surfaces and better preparation margins as they use the inLab MC X5 and the corresponding and extensive list of validated materials. User convenience has been further improved based on extensive user feedback. New software functions for user guidance supports a fast, intuitive CAM workflow. For example, users now have a complete, clear overview of all information regarding available magazines, tools, their service lives and replacement requirements via the new graphic tool and process start management.