Metal artefact reduction results in sharper 3D X-rays. 3D cut-aways enhance patient communication, and software innovations for optimal implant planning.

Metal artefacts can cause distortions in 3D X-ray technology making diagnosis more challenging, particularly for patients with numerous metal restorations.. With MARS (Metal Artefact Reduction Software) Sirona, the dental technology leader, has introduced software that reliably removes metal artefacts from 3D images by making calculations based on new algorithms. This considerably improves image quality and simplifies diagnosis. ?The new software ensures that 3D images are sharper and X-ray machines are more efficient and user-friendly,? said Jörg Haist, Product Manager at Sirona. ?MARS is the intelligent system for reducing metal artefacts, and once again shows how Sirona is leading of the industry in software development.?

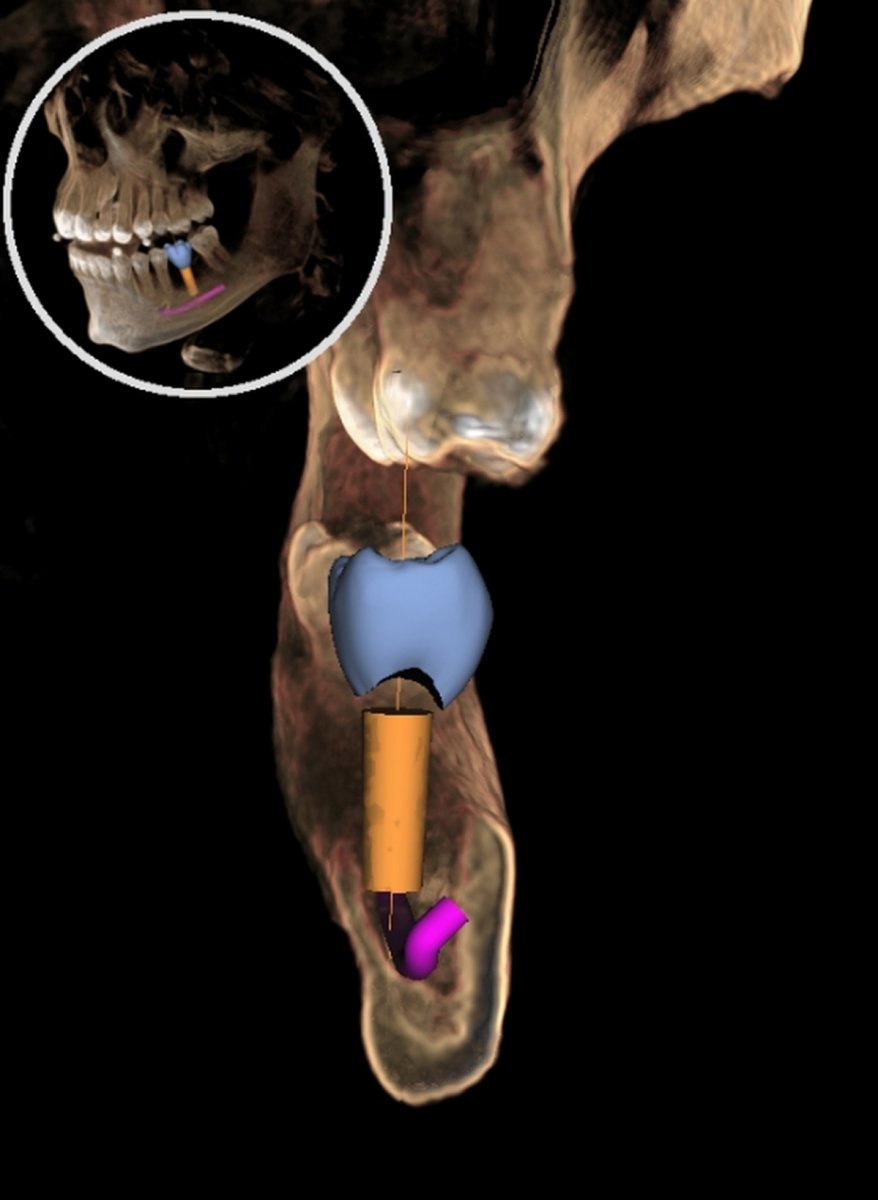

A new software tool for GALILEOS Implant allows the practioner to make three dimensional slices in their 3D images, giving dentists and patients a more detailed view of anatomy and areas of interest. This function improves patient communication as the three-dimensional, cross-sectional images are easier for patients to understand.

Other software developments have enhanced implant planning, saving time and expense and facilitating gentler treatments. In addition to the implant databank, GALILEOS Implant now has a library of abutments for implant manufacturers, enabling abutment, implant and prosthesis planning to be carried out simultaneously at the start of the treatment.

With the Galileos CEREC integration tool, digital impressions taken with the CEREC Bluecam can be superimposed over the Galileos 3D X-ray scan. The dentist can them virtually place the implant in the optimal position and then to send the data digitally to SICAT, Sirona’s subsidiary, for fabrication of a SICAT OPTI guide drilling template Digital transmission of the data results in faster turnaround times and the elimination of postal delays resulting in greater convenience for practitioner and patient.

In the future, CEREC users will able to mill drilling templates directly on their CEREC MC XL milling unit. This in-house solution helps the dentist to place implants quickly and cost-effectively resulting in a faster and more value added procedure.

MARS expedition into the world of 3D : The discovery of a higher image quality

InfoWeb Marketplace