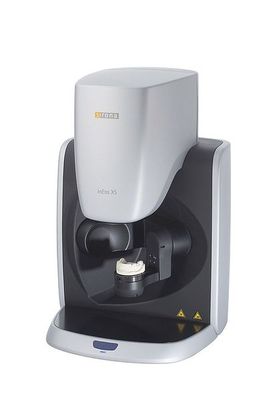

Sirona's new CAD/CAM scanner reliably covers all digitalization tasks in the dental laboratory. It combines a very short, highly precise measurement with operating flexibility and new functions, making it an all-rounder for the dental lab.

The latest technology, an extensive set of functions and a broad range of indications at an attractive price – that is what Sirona offers its customers with the new inEos X5 extraoral scanner. The new functions improve the workflow in the dental lab and reduce idle time for the dental technician.

The inEos X5 can be used to scan impressions and models of all or part of the jaw manually or automatically. The new operating concept increases flexibility for the dental technician so that the scanning process can be optimally integrated into the workflow of the laboratory. While the manual scanning mode saves time for simpler operations, the fully automatic scanning mode has its benefits especially with regard to extensive operations: It shortens the work time and reduces the steps required by the user. In addition, the data volume is optimized and the subsequent calculation of the model is accelerated.

High-tech camera with many advantages

Like its predecessor inEos Blue, the fast scanning speed of the inEos X5 is unsurpassed. The large image field allows the camera to capture four to five teeth per image and an entire jaw with a total of five images. This is how it digitalizes one single crown in less than ten seconds, a three-unit bridge construction in only 30 seconds, as well as an entire jaw in less than one minute. A completely new optical system is used for the scan, which is based on the digital pattern projection: The considerably improved accuracy of less than 12 µm and the camera's autofocus guarantee high-quality scan data that is also suitable for procedures that require the highest degree of accuracy, such as the most demanding implant operations. Due to the camera's greater depth of definition, the inEos X5 can also capture the entire jaw including the palate, which makes it possible to create a digital construction of model casting works.

Improved handling for new and experienced users

With an innovative five-axis technology including rotation arm and intelligent scan planning, the inEos X5 positions and captures models with all indications automatically. This standardizes the images, eliminates user error and speeds up the imaging process. That means that new users in particular can digitalize traditional procedures without requiring significant training. Altogether, the inEos X5 stands out due to its easy handling: The large and open operating area allows all standard articulators to be positioned as well as quick access to the model. With the universal model and impression tray holder, all conventional model support and split cast systems, as well as impression trays in all sizes, can also be used. The multi-die scanning offers advantages in cases where the proximal contacts cannot be seen well and in the fabrication of frameworks and copings for single restorations. With this function, up to four prepared stumps can be positioned in a special holder and digitalized at the same time.

The inEos X5 has been available at retailers since May 2013. The list price including PC and inLab software as well as the OPEN inEos interface is EUR 19,990.

Overview of new inEos X5 features:

- A combination of manual and fully automatic operation

- High accuracy

- Time savings and improved workflow due to the five-axis technology and autofocus

- Large scan field and good depth of definition

- Multi-die scanning for up to four individual stumps

- Universal model and articulator holders

- Easy handling